A study on the performances of PEGDA and PEDOT: PSS composite resin for 3D-printed biosensor applications

Main Article Content

Article Sidebar

Abstract

As medical advancement, the quality of human life improves, and it is undeniable that biochemical monitoring using a biosensor plays an important role in medical treatment. At this moment, there are many biosensors fabricated to detect analytes in human biofluids through transdermal [1]. The 3D printing technique has gained attention to fabricate wearable biosensing devices by using photocurable resin, as it is low cost and less time-consuming while providing high-resolution [2]. Polyethylene glycol diacrylate (PEGDA) is a biocompatible and photocurable polymer to be printed by vat polymerization 3D printing for medical devices [3]. However, the PEGDA does not show the conductivity potential which is an essential property for the biosensing electrode. To overcome this limitation, conducting materials are introduced. Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (PEDOT: PSS) is an alternative material that is commonly exploited to enhance conductivity. It also possesses several potentials such as biocompatibility, high conductivity, easy managing as it is transparent [4], and relatively inexpensive in comparison with other conductive metals e.g. gold, silver, and platinum. Thus, PEDOT: PSS is an alternative material used to improve conductivity for the photocurable resin.

There are several reports about using the as received PEDOT: PSS as the resin filler, treating the PEDOT: PSS with H2SO4 to remove some PSS which enhanced conductivity as well as removed liquid from the as-received PEDOT: PSS solution [5], and using freeze-drying the as received PEDOT: PSS to remove liquid and employing the dried PEDOT as conducting materials [6]. However, there is no comparison of the electrical property and electrochemical behavior for polymers that the PEDOT: PSS are prepared from those different methods.

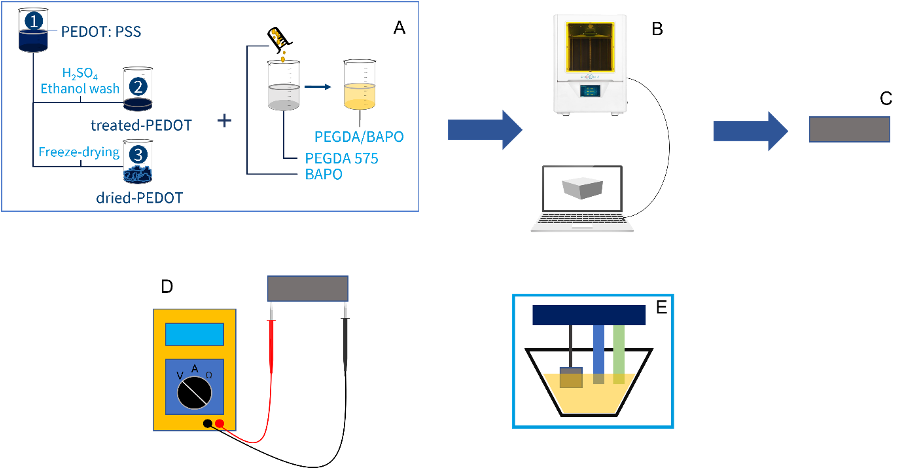

Here we first investigated a comparison of PEGDA and PEDOT: PSS blend prepared by three recipes. To prepare photocurable, resin matrix was prepared by adding different ratios of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide (BAPO) to Poly(ethylene glycol) diacrylate (PEGDA 575). From now the mixture would be called as PEGDA followed by the BAPO ratio. For example, PEGDA1% is for PEGDA 575 with 1% of BAPO. Three different types of PEDOT: PSS were studied for conductivity. As received PEDOT: PSS was the first type of filler [7]. The second type of conductive filler was the PEDOT: PSS which was treated to remove some insulated PSS. The as-received PEDOT: PSS was diluted with 0.5 M H2SO4 solution for 12 hours. The H2SO4 helped reduce the coulombic force between PEDOT and PSS in the solution and rearrange PEDOT conformation from random to linear as well as enhance conductivity. After 12 hours, the supernatant was removed, and the precipitate was centrifuged at 4000 rpm for 10 minutes. The remaining supernatant was removed, and the precipitate was washed in ethanol and centrifuged for another 10 minutes at 4000 rpm to recover the PEDOT. The final precipitate was used as the second type PEDOT: PSS and called treated-PEDOT (t-PEDOT) [5]. The last type of PEDOT: PSS was dried-PEDOT: PSS. The as-received PEDOT: PSS was placed at -80 °C for 24 hours and freeze-drying for 72 hours to remove liquid in the solution. The PEDOT: PSS solution became pure and dried. This type of PEDOT: PSS was called d-PEDOT [6]. To achieve conductive photocurable resin, different ratios of PEGDA were used as a matrix base, and different types of PEDOT: PSS were added with different ratios (see Fig. 1A). Additionally, 5% DMSO was added to improve the dispersion and slow precipitation of the PEDOT agglomerates [3]. The mixtures were ultrasonicated for different periods with the pulse of 10 seconds on and 5 seconds off and cooled in ice water during the ultrasonication process.

Siemens NX software (version NX1953) was exploited to create a 3D prototype of the electrode. The 3D file (.stl) was sliced into the sliced file (.photons) that was compatible with the printer by the printing software (Photon Workshop). The file was then transferred to a 3D printing machine (Anycubic, Photon S) to print the electrode pattern (see Fig. 1B). Once the printing process was done, the excessive resin was washed with Isopropanol. The clean object was then cured with 405 nm wavelength of UV to enhance stability. The different ratios of PEGDA and PEDOT were mixed by using the ultrasonicator for 20 minutes. Centrifugation was employed for precipitation testing. The composite polymers were printed for 1x1x5 cm3 and tested for resistivity using the two-probes multimeter (see Fig. 1D). To examine electrochemical behavior, the printed polymer was used as a working electrode with a Ag|AgCL reference and Pt wire as a counter electrode, and tested using cyclic voltammetry in 5 mmol L-1 K3Fe(CN)6 (see Fig. 1E).

Fig.1. Schematic of all this whole process of the experiment: A. Resin preparation with different recipes B. 3D printing of the composite polymer C. the printed polymer. D two-probes multimeter for resistivity testing and E. cyclic voltammetry and electrical properties.

The different recipe preparation would affect electrical properties and electrochemical behavior of the printing polymers. The optimized condition of this composite ratio would be a useful material for fabricating a wearable or implantable biosensor. We hoped that this alternative material would be used for a medical device instead of a metal such as gold or platinum. This would decrease the cost of medical devices to be more affordable.

How to Cite

Article Details

3D printing, Biomedical sensor, PEDOT:PSS, Photocurable resin

https://doi.org/10.1007/s10544-018-0349-6

[2] S. S. Athukorala et al., “3D printable electrically conductive hydrogel scaffolds for biomedical applications: A review,” Polymers (Basel)., vol. 13, no. 3, pp. 1–21, 2021 https://doi.org/10.3390/polym13030474

[3] G. Scordo et al., “A novel highly electrically conductive composite resin for stereolithography,” Mater. Today Commun., vol. 19, no. November 2018, pp. 12–17, Jun. 2019

https://doi.org/10.1016/j.mtcomm.2018.12.017

[4] A. Salim and S. Lim, “Recent advances in noninvasive flexible and wearable wireless biosensors,” Biosens. Bioelectron., vol. 141, no. April, p. 111422, Sep. 2019

https://doi.org/10.1016/j.bios.2019.111422

[5] H. Rastin, B. Zhang, J. Bi, K. Hassan, T. T. Tung, and D. Losic, “3D printing of cell-laden electroconductive bioinks for tissue engineering applications,” J. Mater. Chem. B, vol. 8, no. 27, pp. 5862–5876, 2020

https://doi.org/10.1039/D0TB00627K

[6] Y.-Y. Lee et al., “A Strain-Insensitive Stretchable Electronic Conductor: PEDOT:PSS/Acrylamide Organogels,” Adv. Mater., vol. 28, no. 8, pp. 1636–1643, Feb.2016

https://doi.org/10.1002/adma.201504606

[7] V. Bertana et al., “3D printed active objects based on the promising PEDOT: PSS resin: Investigation of their integration inside an electronic circuit,” Int. J. Eng. Res. Technol., vol. 13, no. 3, pp. 462–469, 2020

https://dx.doi.org/10.37624/IJERT/13.3.2020.462-469