Future prospects of rear earth element free materials for thermoelectric generators

Main Article Content

Article Sidebar

Abstract

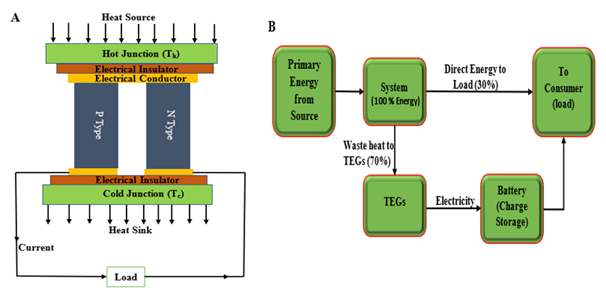

The accelerated research to overcome the utilization of fossil fuel to grapple challenges, like rising power cost and global warming, lead to a new domain of clean and renewable energy harvesting i.e., Thermoelectric generators (TEGs). A TEG is a solid-state device that transforms waste heat energy directly into electricity by utilizing the Seebeck effect when subjected to a temperature gradient[1]. The source of waste heat is numerous. For example, it has been found that 60-70% of energy produced in automobile energy is lost in the form of heat to surrounding with just 20 to 30% of the fuel being converted into usable energy[2]. Structurally, a TEG system is predominantly composed of P and N-type Semiconductors as shown in Figure 1(A). To generate the necessary power, an efficient TEG module is created by clustering a number of TE blocks which are connected electrically in series and thermally in parallel[3]. A simple workflow for energy extraction from TEG module is shown in figure 1(B). TEGs have gained interest because these are eco-friendly in nature, maintenance free, limited in dimension, versatile power source with no mechanical parts, hence noise free, and having high reliability for installation in severe conditions like offshore platform, deserts, and remote sites.

Fig.1A. Schematic of TEG module B. TEG work flow for energy harvesting.

The efficiency of TEGs is characterized by the dimensionless quantity called figure of merit (ZT)[4]. The ZT plays an important role as it determines the overall sustainability of TEGs. The ZT should be large to achieve high thermoelectric efficiency. However, the interdependence of parameters associated with ZT limits the efficiency of TEGs. A material with ZT greater than 1 is an promising TEG material [5], but ZT greater than 3 is enough to replace conventional energy generating technology (challenging). The material selection plays an important role in energy conversion (TEGs) efficiency. Various factors are considered before selection like cost, availability, mass production, doping process and environmental aspects. Conventionally, majority of TEGs are composed of rare earth materials because these elements show higher thermal stability, high ZT values, and properties of insulators for charge storage. For instance, bismuth telluride based materials are widely used in TEG modules (about 70% of total installations) [6]. Rare earth material show higher ZT values by using different technique; Bi2Te3 (ZT=2.8), Bi0.4Sb1.6Te3 (ZT=1.36), Sb1.85In0.15Te3 (ZT=0.27), Bi0.5Sb1.5Te2.7Se0.3 (ZT=0.48), Bi2−xSbxTe3 (ZT=0.8), Bi0.48Sb1.52Te3 + PbTe composite (ZT=0.9), Bi0.5Sb1.5Te3 (ZT=1.7), Bi0.5Sb1.5Te3 (ZT=1.2), (BiSbTe1.5Se1.5)0.3Ag0.3 (ZT=.48), Bi2Te3 nanostructure (ZT=1.6), PbTe PbSe (ZT=1.8), PbSe (ZT=1.7), Sn with Se, Te (ZT=2.6), Yb13.82Pr0.18Mn1.01Sb10.99 (ZT=1.2), PbTe/PbSeTe Superlattices (ZT=2.4), PbTe–SrTe doped with Na (ZT=2.20). Harman et al.[7] obtained ZT of ~3 in Bi doped PbSeTe/PbTe Quantum dot Superlattices, but is challenging for large scale harvesting due to heat transfer and mass production. Ge doped clathrates, result in valence and conduction band minima and an insertion of rare earth element (Eu2+, Yb2+) result in decrease of thermal conductivity. Insertion of Ce3+ and la3+ in Si with Au result in 50% of seebeck coefficient. In short, insertion of rare earth materials results in ZT improvement, hence reduce thermal conductivity, increase Seebeck coefficient and charge transport.

Although, Te (Tellurium) based compounds show higher efficiency, however the drawbacks are limitless, like; 1) The scarcity of tellurium (Te) in the earth's crust, only approximately 0.001 ppm, far less than that of gold availability, which is 0.004 ppm, 2) the cost is too high (when compared with PbS, Bi2Te3 is 10 times more expensive), 3) poisonous in nature, 4) low operating temperature range (due to low bandgap, oxidizing and vaporizing nature). Hence, the present technology demands approach towards novel materials with high melting point, high electrical conductivity, low thermal conductivity, high seebeck coefficient, and operating temperature with higher ZT values and minimum use of rare earth materials. Therefore, in our present paper, we have covered various conventional materials with corresponding ZT values and the factors governing rise in efficiency, and aaccordingly alloys, Skutterudites, Half-Heusler’s, clathrates are covered in details. To mention a few, MgAgSb came in existence with replacement of Te and when doped with Ti, Yb, Zn, and Ca the ZT obtained is 0.75, 1.14, 0.48 and 0.75 respectively [8]. A number of scarce metals are replaced in similar way with advanced efficient materials, and hence the minimization of use of rare earth materials seems to be possible in near future.

How to Cite

Article Details

[1] B. Russ, A. Glaudell, J.J. Urban, M.L. Chabinyc, and R.A. Segalman, Nature Reviews Materials, 1, 16050 (2016). https://doi.org/10.1038/natrevmats.2016.50.

[2] S. Twaha, J. Zhu, Y. Yan, and B. Li, Renewable and Sustainable Energy Reviews, 65, 698–726 (2016). https://doi.org/10.1016/j.rser.2016.07.034

[3] Z. Niu, S. Yu, H. Diao, Q. Li, K. Jiao, Q. Du, H. Tian, and G. Shu, International Journal of Heat and Mass Transfer, 85, 12–32 (2015).https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.107.

[4] X. Zhang and L.-D. Zhao, Journal of Materiomics, 1, 92–105 (2015). https://doi.org/10.1016/j.jmat.2015.01.001

[5] T. Hendricks and W.T. Choate, “Engineering Scoping Study of Thermoelectric Generator Systems for Industrial Waste Heat Recovery”, (2006). https://doi.org/10.2172/1218711

[6] M. Karami Rad, A. Rezania, M. Omid, A. Rajabipour, and L. Rosendahl, Renewable Energy, 138, 236–242 (2019). https://doi.org/10.1016/j.renene.2019.01.104

[7] T.C. Harman, M.P. Walsh, B.E. Laforge, and G.W. Turner, Journal of Electronic Materials, 34, L19–L22 (2005). https://doi.org/10.1007/s11664-005-0083-8

[8] Z. Soleimani, S. Zoras, B. Ceranic, S. Shahzad, and Y. Cui, Sustainable Energy Technologies and Assessments, 37, 100604 (2020). https://doi.org/10.1016/j.seta.2019.100604

https://orcid.org/0000-0002-4512-1936

https://orcid.org/0000-0002-4512-1936