Phase Transition in PVDF-TrFE/Hyperbranched Polyester (90/10) Blend Thin Film during Heating-Cooling Cycle using FTIR Spectroscopy

Main Article Content

Article Sidebar

Abstract

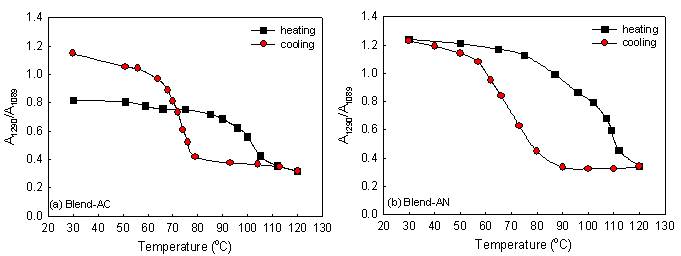

Ferroelectric polymers such as polyvinylidene fluoride (PVDF) and its copolymer with trifluoroethylene (TrFE) have been widely used as energy-harvesting nanogenerator and non-volatile memory device [1-3] because of their flexible film forming nature as well as piezoelectric [4] and ferroelectric [5] characteristics, respectively. Compared to neat PVDF, the PVDF-TrFE copolymer is expensive but considered as superior to PVDF in terms of higher crystallinity, remnant polarization and piezoelectric response. PVDF-TrFE exhibits β-crystalline phase spontaneously, whereas PVDF requires either mechanical drawing of the α-phase, casting from high polar solvents, electrical poling or crystallization from melt for exhibiting higher β-crystalline phase. Hence, the focus of researchers working in this field is to study the crystalline phase transition in PVDF-TrFE and the ways to enhance the ferroelectric β-crystalline phase in PVDF-TrFE suitable for flexible electronic applications. Many research groups have used additives such as metal oxides [6], CNT [7], nanoparticles [8], etc. in PVDF-TrFE to improve its ferroelectric crystalline phase, to study the polymorphic changes and to reduce its cost of usage in electronic applications. Considering the aforementioned characteristics, in the present work, we have studied the crystalline phase transition changes in spun-cast PVDF-TrFE/hyperbranched polyester (HBP) (90/10 wt.%) blend film deposited on KBr substrate (designated as Blend-AC sample) and annealed at 130 oC (designated as Blend-AN sample). Our first objective is to study the phase transition behavior of the blend sample by subjecting the blend AC and AN thin film samples to heating-cooling (30→120→30 oC) cycle by FTIR-Transmission Spectroscopy (TS). From FTIR data, it was found that the absorption intensity of A1 band at 1289.5 cm-1 for AC and 1292 cm-1 for AN is decreased gradually during heating for both the samples. However, it is increased for 30C condition for AC sample whereas it comes to the initial intensity for AN sample for 30C condition. Fig. 1 shows the relative amount of ferroelectric crystalline phase for both AC and AN blend thin film samples as a function of heating-cooling cycle. The Blend-AC and Blend-AN thin film samples exhibit irreversible and reversible phase transitions, respectively. Our second objective is to apply Factor analysis of FTIR-TS heating-cooling data. It was found that the AN sample exhibited reversible phase transition (70%↔70%) while the AC sample displayed irreversible transition (50%↔70%).

Fig.1. FTIR-TS: Relative amount of ferroelectric β-crystalline phase in PVDF-TrFE/HBP (90/10) blend thin film sample (a) AC and (b) AN as a function of heating-cooling cycle.

Acknowledgement: This work was supported by the Industrial Strategic Technology Development Program (Grant No. 10047976) funded by the Ministry of Trade, Industry & Energy (MOTIE, KOREA). One of the authors (A.A.P) also wish to thank CSIR, Government of India for supporting this study under CSIR-EMR-II scheme (03(1450)18/EMR-II dt.05-06-2018).

How to Cite

Article Details

PVDF-TrFE, hyperbranched polyester, phase transition, ferroelectric phase, FTIR

https://doi.org/10.1063/1.3691825

[2] T. Sharma, S. Je, B. Gill, J.X.J. Zhang, Sens Actuator A Phys 177, 87–92 (2012). https://doi.org/10.1016/j.sna.2011.08.019

[3] H. Li, R. Wang, S. Han, Y. Zhou, Polym Int 69, 533–544 (2020).

https://doi.org/10.1002/pi.5980

[4] H.J. Kawai, Jap J Appl Phy 8, 975–976 (1969).

http://dx.doi.org/10.1143/JJAP.8.975

[5] T. Furukawa, M. Date, E. Fukada, Y. Tajitsu, A. Chiba, Jap J Appl Phys 19, L109 (1980).

https://doi.org/10.1143/JJAP.19.L109

[6] S.C. Karumuthil, S.P. Rajeev, S. Varghese, ACS Appl. Nano Mater 2, 4350–4357 (2019). https://doi.org/10.1021/acsanm.8b02248

[7] A. Wang, M. Hu, L. Zhou, X. Qiang, Nanomaterials, 8, 1021 (2018).

https://doi.org/10.3390/nano8121021

[8] H. Paik, Y. Choi, S. Hong, K. No, Scientific Reports 5, 13209 (2015).

https://doi.org/10.1038/srep13209